Automated Valves

In the modern manufacturing process, automation plays a vital role. It reduces the cost of production as well as time with 100% accuracy.

We provide automation packages like valves with Pneumatic /Electric actuators along with accessories like Solenoid Valves, Limit Switches, Air Filter Regulators, etc.

Valves such as Ball, Butterfly, Gate, Globe, Diaphragm, etc. are usually used for automation.

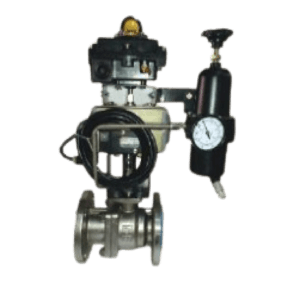

Ball Valve

Description

- Ball valves are controlled by Pneumatic actuators, which convert compressed air energy to mechanical motion.

- A ball valve requires rotating mechanical action to make a 90-degree turn.

- Pneumatic actuator ball valves can be either single- or double-acting. A single-acting Pneumatic actuator turns a valve with a single compressed air input and then returns it to its usual position with a spring.

- A double-acting Pneumatic actuator uses two compressed air inputs to turn the valve and return it to its original position.

- The rack and pinion mechanism is the most popular Pneumatic actuator for Ball Valves. This consists of the rack (a linear gear) and the pinion (a circular gear).

- The rack is connected to a piston that is pushed by compressed air to achieve linear motion.

- The pinion converts the linear motion into circular motion. The pinion moves the stem of a ball valve to open and close positions.

- Solenoid valves regulate compressed air flow to the Pneumatic actuator for Ball Valves.

- Electrical impulses from the controller cause the solenoid valve to open or close, allowing compressed air to flow through both piston sides of the Pneumatic actuator.

- The piston pushes the rack, which turns the pinion that is attached to the Ball Valve stem.

Butterfly Valve

Description

- The Pneumatic Butterfly Valve absorbs and controls dry and lubricated gases via positioners, solenoid valves, or other equipment before transmitting them to the cylinder of the Pneumatic actuator. This is the air source that allows the Pneumatic actuator to work.

- When the internal air source is introduced into the Pneumatic actuator’s air chamber, the air pressure acts on the piston, causing the generated thrust to rotate the output shaft as well as the valve stem and butterfly plate, completing the butterfly valve’s opening and closing action.

- Adding a valve positioner to the Pneumatic Butterfly Valve allows for accurate opening control of the valve.

- Furthermore, an intelligent positioner can be utilized to link to the field bus, allowing the Pneumatic Butterfly valve’s functioning state to be detected and diagnosed.

- The Pneumatic actuator allows the Pneumatic Butterfly Valve to open and close flexibly and fast, ensuring pipeline safety.

- It is a control valve commonly used in industrial pipes.

Our Clients